Don't worry, contact your boss immediately

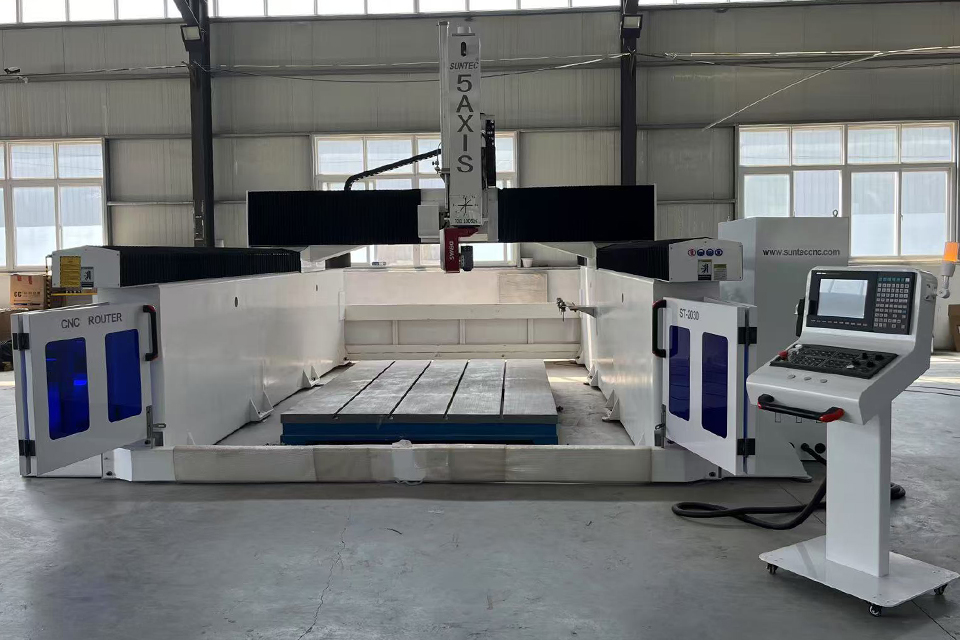

Energy-saving tips for high-axis CNC operations provide a comprehensive overview of strategies and practices aimed at reducing energy consumption in computer numerical control (CNC) machining processes, particularly in high-axis operations. CNC machines are crucial in modern manufacturing, known for their precision and efficiency in producing complex components for various industries, including aerospace, automotive, and electronics. However, the significant electricity consumption associated with these machines has raised concerns regarding operational costs and environmental sustainability, prompting a need for energy-efficient solutions.

The energy efficiency of CNC operations can be influenced by several factors, including machine type, operational parameters, and the implementation of advanced technologies such as variable frequency drives (VFDs) and regenerative power systems. Studies have demonstrated that adopting energy-efficient technologies can lead to reductions in energy usage by up to 30%. Additionally, optimizing machine operation parameters, utilizing advanced software for tool path optimization, and implementing real-time monitoring can further enhance energy savings and operational performance.

Notably, transitioning to energy-efficient practices not only helps manufacturers reduce costs but also contributes to broader environmental benefits by lowering carbon emissions associated with energy consumption. The source of electricity used in CNC operations significantly impacts their environmental footprint, with renewable energy sources presenting a more sustainable option. Furthermore, the economic benefits of energy savings can improve competitiveness and innovation within the manufacturing sector, creating a dual advantage of cost reduction and enhanced sustainability.

However, the implementation of energy-saving techniques is not without challenges. Manufacturers may face barriers such as resistance to change, the complexity of operations, and the initial costs of investment in new technologies. Addressing these challenges requires a strategic approach, including staff training, ongoing maintenance, and a commitment to sustainable practices that align with industry trends toward reducing ecological footprints. Overall, energy-saving tips for high-axis CNC operations represent a vital component of modern manufacturing practices, aiming to foster a more efficient, cost-effective, and environmentally responsible industry.

Computer Numerical Control (CNC) machines are integral to modern manufacturing, renowned for their precision and efficiency in producing complex components across various industries, including aerospace, automotive, and electronics. However, the electricity consumption of these machines poses significant implications for both operational costs and environmental sustainability.

The energy consumption of CNC machines can vary widely depending on several factors, including machine type, operational parameters, and the technology employed. For instance, the use of energy-efficient technologies, such as variable frequency drives (VFDs) and energy-efficient motors, can greatly reduce electricity usage. Studies have shown that the implementation of such technologies can lower energy consumption by up to 30% in some cases. Furthermore, the efficiency of energy usage is influenced by the machine’s operational efficiency, which is reflected in metrics such as power or energy consumption during machine uptime.

The source of electricity also plays a critical role in determining the environmental impact of CNC machine operations. Electricity generated from renewable sources carries a lower carbon footprint compared to that from fossil fuels. As manufacturers increasingly turn to renewable energy providers, they can significantly diminish their carbon emissions, thereby contributing to global efforts in combating climate change.

To enhance energy efficiency, manufacturers can adopt a variety of best practices. These include optimizing operating parameters, implementing auto power-off settings for auxiliary components, and utilizing regenerative supply modules that recover energy during operations. For instance, regenerative braking systems in CNC machines can convert kinetic energy back into electrical energy, which can then be reused in the machine or returned to the power grid.

Additionally, understanding the energy consumption profile of CNC machines allows for targeted energy-saving initiatives. By analyzing the machine’s operational cycles and adjusting parameters to minimize idle times and energy wastage, manufacturers can achieve substantial energy savings.

The drive towards energy efficiency in CNC machining not only results in lower operational costs but also fosters economic stability and competitiveness within the manufacturing sector. By reducing electricity costs, manufacturers can allocate resources to innovation and development, ultimately enhancing their market position. Moreover, embracing energy efficiency contributes to resource conservation and helps mitigate the environmental degradation associated with energy production and consumption.

Optimizing energy consumption in high-axis CNC operations can significantly enhance operational efficiency while reducing environmental impact. Various strategies can be employed to achieve these objectives.

One of the most effective ways to save energy is by optimizing the machine’s operation parameters, including cutting speed, feed rate, and depth of cut. Adjusting these parameters can help improve machining efficiency and reduce energy consumption. For instance, a low cutting speed can lead to inefficient machining, while excessively high speeds may cause tools to wear out more quickly, requiring frequent replacements and ultimately increasing energy use.

Implementing energy recovery systems, such as shared-bus or common power supply drive systems, can allow CNC machines to reconsume regenerated power instead of returning it to the main power line. This approach can be particularly beneficial for larger machines, which often have higher power returns when braking. Smaller machines may also adopt this technology as energy prices rise and operational efficiency becomes more critical. By utilizing a power bridge, these systems manage and repurpose energy to match the frequency and phase of the main power supply, enhancing energy efficiency during machining operations.

Retrofitting existing CNC machines with variable frequency drives (VFDs) has been shown to result in significant energy savings. For example, one metalworking company reported a 20% reduction in electricity consumption after such an upgrade. Additionally, upgrading to energy-efficient motors can yield substantial savings, with some aerospace manufacturers achieving a 25% reduction in electricity use by replacing older motors.

Employing advanced software to optimize tool paths can also lead to reduced machining time and energy usage. A case study from an automotive parts manufacturer indicated a 15% decrease in energy consumption through the optimization of tool paths, which allowed for more efficient material removal and reduced cycle times.

Implementing predictive maintenance strategies through data analytics can help identify potential issues before they lead to equipment failure. By utilizing real-time monitoring, CNC systems can automatically adjust process parameters, ensuring machines operate under optimal conditions and reducing unnecessary energy consumption. Regular maintenance, including scheduled checks of coolant levels and tool wear, is essential for maintaining efficiency and minimizing downtime.

Integrating sustainable manufacturing practices not only reduces energy usage but also conserves natural resources, contributing to a more responsible use of finite resources. This approach can mitigate the environmental impacts associated with energy consumption and ensure that resources remain available for future generations.

By employing these strategies, CNC operations can significantly reduce their energy consumption, leading to both environmental and economic benefits, while enhancing overall manufacturing efficiency.

To enhance energy efficiency in high-axis CNC operations, one effective strategy is to implement a shared-bus or common power supply drive system. This approach allows for the reconsumption of regenerated power within the machine by fine-tuning the machining cycle. For example, a machine can accelerate one motor while another decelerates, thus optimizing energy use during operation. Additionally, utilizing cycle analysis tools, while commercially available, is not strictly necessary. Operators can achieve significant energy savings by observing and adjusting key parameters, such as tool change cycles, to minimize power consumption during non-cutting phases.

Minimizing cycle times is crucial for conserving energy in high-axis CNC machining. High spindle speeds during machining can lead to more efficient energy use per unit of material removed. High-speed machining maintains a constant power while allowing for variable power usage, which can dramatically improve efficiency. Furthermore, machine tool builders are increasingly offering designs that facilitate quicker acceleration and deceleration through features like twin ballscrews and twin motors. These enhancements can result in cycle time reductions of up to 20 to 30 percent compared to traditional setups.

Incorporating automation and robotics can significantly reduce energy consumption in CNC operations. For instance, automated tool management systems ensure that the correct tools are available when needed, reducing machine downtime and enhancing overall equipment effectiveness (OEE). Collaborative robots (cobots) can work alongside CNC machines to handle tasks such as tool changing and part inspection, which increases productivity while minimizing manual intervention. This not only streamlines operations but also optimizes energy usage across the manufacturing process.

Utilizing advanced simulation and optimization software is key for high-axis CNC operations. These tools create virtual models of CNC processes, allowing manufacturers to simulate the machining environment before physical operations begin. This helps identify potential inefficiencies, such as tool wear and vibrations, and facilitates proactive adjustments to enhance energy efficiency and reduce waste. Moreover, selecting appropriate CAD/CAM software for CNC operations can optimize machine operations and minimize energy use by generating efficient toolpaths and reducing unnecessary movements.

Emphasizing the use of eco-friendly materials in high-axis CNC operations contributes to sustainability efforts and can enhance energy savings. Multi-axis CNC machining enables manufacturers to select materials that not only meet quality standards but also reduce overall waste during production. This approach aligns with industry trends aimed at minimizing ecological footprints while maintaining high production efficiency.

By integrating these strategies into high-axis CNC operations, manufacturers can achieve significant energy savings, enhance productivity, and contribute to more sustainable manufacturing practices.

Energy-saving techniques in high-axis CNC operations are crucial for enhancing efficiency and reducing operational costs. These methods can significantly minimize energy consumption while maintaining optimal machining performance.

One of the most effective approaches to save energy is by optimizing the operation parameters of CNC machines. Adjustments to cutting speed, feed rate, and depth can lead to substantial reductions in energy usage during machining processes. For example, by fine-tuning the tool change cycle so that the spindle decelerates concurrently with the Z-axis acceleration towards the tool magazine, energy consumption can be minimized during these transitions.

Another innovative energy-saving technique involves the use of a shared-bus or common power supply drive system to reconsume regenerated power instead of returning it to the main line. This system allows for more efficient energy use by analyzing and tuning the machining cycle, enabling one motor to accelerate while another decelerates, thereby optimizing overall energy consumption.

Employing monitoring software such as Energy Dashboard Plus can provide insights into power consumption trends across multiple machines within a factory. This software links power usage to machining programs and tools, offering detailed reports on daily, weekly, and monthly energy consumption as well as CO₂ emissions. Such visibility enables operators to identify areas for potential savings.

Utilizing advanced software for toolpath optimization is another effective method. By implementing simulation software and high-speed machining strategies, CNC operators can decrease cycle times and enhance energy efficiency. Optimizing toolpaths not only contributes to energy savings but also improves overall machining performance.

Effective coolant management plays a vital role in energy conservation. Utilizing the correct type and quantity of coolant, along with advanced cooling systems such as minimum quantity lubrication (MQL) and dry machining technologies, can significantly reduce energy and coolant consumption.

Implementing energy-efficient technologies, such as optimized servo motors and automatic standby modes, helps decrease energy consumption without sacrificing accuracy. These technologies can be integrated into CNC machines to ensure they operate more efficiently, particularly during idle periods.

In addition to the direct energy savings, these techniques contribute to broader community and economic benefits. By reducing energy costs, manufacturers can achieve greater competitiveness and stability, while also generating new opportunities in green technologies and energy management. Furthermore, transitioning to energy-efficient practices mitigates environmental impacts, leading to improved public health outcomes by reducing air and water pollution.

By integrating these energy-saving techniques into high-axis CNC operations, manufacturers can achieve significant energy savings while also enhancing operational efficiency and sustainability.

Two case studies were conducted to demonstrate the effectiveness of a function blocks-based energy demand model in real machining systems. The first study revealed the influence of process planning decisions on energy consumption during CNC milling operations, showing a significant correlation between planning and energy efficiency. The accuracy of the energy model used in these studies was impressive, achieving 95.3% accuracy in predicting actual energy consumption, underscoring the potential for informed decision-making in manufacturing processes.

In addition to energy modeling, a costing model based on machining experiments was presented, accompanied by an industry-based case to estimate potential cost savings. This model highlighted how strategic planning and implementation of efficient practices can lead to significant economic benefits for manufacturers, emphasizing the importance of combining cost analysis with energy-saving strategies.

The studies also demonstrated how the integration of advanced technologies contributes to reduced energy consumption and operational costs. For instance, manufacturers that retrofitted their CNC machines with variable frequency drives (VFDs) reported up to a 20% reduction in electricity consumption, while optimized tool paths could lower machining times and energy usage by approximately 15%. Moreover, aerospace manufacturers that upgraded to energy-efficient motors achieved a 25% reduction in electricity consumption, illustrating the substantial impact that targeted technological improvements can have on both energy efficiency and overall operational performance.

These case studies collectively illustrate the importance of employing data-driven approaches and advanced technologies to foster energy efficiency in CNC operations, ultimately leading to both economic and environmental benefits.

Implementing energy-saving techniques in high-axis CNC operations presents several challenges that can hinder efficiency improvements and cost reductions.

One of the primary challenges is the understanding of energy consumption requirements for various machines and operations. Larger machines typically consume more energy, making it essential to monitor and manage their energy usage to prevent overheating or short circuits, which can lead to significant operational downtime and damage to the equipment. Failure to effectively track and control energy consumption can result in missed opportunities for savings.

The complexity of CNC machining processes can also pose challenges. Parts with intricate designs require advanced programming and precision control, which extends setup times and often necessitates the use of more expensive multi-axis machining centers. This complexity not only increases production costs but can complicate the implementation of energy-saving strategies, as optimizing machining parameters may require more sophisticated solutions.

Another significant barrier is the potential resistance to change among operators and management. Transitioning to new technologies or operational strategies can be met with skepticism, particularly if stakeholders are accustomed to existing processes. Moreover, integrating predictive maintenance and data analytics to monitor energy use may require training and investment that some organizations may be reluctant to undertake.

While energy-saving techniques can lead to long-term savings, the initial investment in new technologies or modifications to existing machinery can be a significant obstacle. Many businesses hesitate to spend large sums upfront, particularly if the payback period for energy-saving measures is unclear. As a result, organizations may forgo potential energy efficiency gains.

Implementing energy-efficient practices often necessitates expertise that may not be readily available within the organization. Consulting with external experts can be a first step towards identifying energy-saving opportunities, but hiring such consultants can introduce additional costs and complexities. Furthermore, ongoing education and training for staff to adopt energy-efficient practices require a commitment of time and resources.

Finally, the integration of data analytics for optimizing energy use presents its own set of challenges. Collecting and analyzing production data can help identify inefficiencies and guide decision-making, but it requires a robust data management infrastructure and skilled personnel to interpret the results effectively. Without proper data management, organizations may struggle to make informed adjustments to their operations that could lead to significant energy savings.

High-volume CNC machining presents several challenges that can impact operational efficiency and overall costs. However, by employing strategic approaches, manufacturers can effectively mitigate these issues and enhance productivity.

One of the most pressing challenges in CNC machining is rapid tool wear due to continuous operation. To address this, manufacturers can implement a rigorous maintenance schedule, ensuring regular inspections and timely replacements of tools. Additionally, investing in higher-quality, durable tools can extend the lifespan of equipment, reducing the frequency and costs associated with replacements.

Managing heat generated during machining is crucial for maintaining tool integrity and product quality. Specialized training for CNC operators is essential to equip them with the skills needed to manage heat effectively and make precise mechanical adjustments. By enhancing the understanding of thermal dynamics in machining processes, companies can minimize heat-related issues.

The demand for skilled labor in CNC machining is high, leading to increased competition and labor costs. To counter this challenge, manufacturers can develop in-house training programs to upskill existing employees. Additionally, establishing apprenticeship programs in collaboration with educational institutions can create a pipeline of skilled workers ready to meet industry demands. Automation and simplification of certain tasks can further reduce reliance on highly skilled labor, making processes more efficient.

Frequent breakdowns and the high cost of spare parts can significantly impact a CNC operation’s bottom line. To minimize repair costs, companies should prioritize preventive maintenance practices, which help reduce the likelihood of unexpected machinery failures. Training in-house technicians to perform basic repairs can also lower costs associated with external service providers, thereby enhancing operational efficiency.

When dealing with large parts, challenges such as handling and logistics, machining time, and tool reach can complicate production. Utilizing cranes for safe handling and employing advanced logistic planning can streamline the movement of large components. Additionally, optimizing cutting speeds and feed rates can reduce machining times without compromising quality. The use of long-reach tools and multi-axis CNC machines can also expand machining capabilities and improve overall output.

Incorporating sustainable practices into CNC operations not only aids in environmental responsibility but also enhances efficiency. Strategies such as lean manufacturing, reducing material waste, and optimizing energy consumption can significantly lower operational costs while attracting environmentally conscious customers. Companies adopting these sustainable approaches often experience improved resource utilization and reduced downtime.

By implementing these strategies, manufacturers can effectively navigate the challenges associated with high-axis CNC operations, ultimately leading to enhanced efficiency, reduced costs, and improved product quality.