Don't worry, contact your boss immediately

SUNTEC CNC delivers industrial-grade automation solutions to 10,000+ factories worldwide.

180° rotating HSD spindle enables complex 3D machining. Premium components (HSD, Yaskawa, Syntec) ensure enhanced durability and sub-0.01mm precision. Hardened steel frame…

180° rotating HSD spindle enables complex machining. Premium components (HSD, Yaskawa, Syntec) ensure long-term precision & reliability. Hardened steel structure guarantees accuracy…

Large-format CNC (3x4m area) with 180° HSD spindle for complex molds (aerospace/shipbuilding). ±0.01mm precision via heat-treated steel frame & Hiwin guides. Premium…

SUNTEC CNC delivers industrial-grade automation solutions to 10,000+ factories worldwide.

Whole Test Aftermachine Finished

Installation

Overloadtest

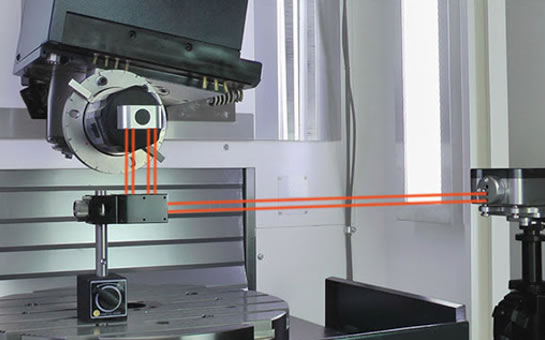

High-Tech Inspection Tools Ensure Assembly Accuracy

Accuracy Detection (RTCP)

Pacific Furniture Manufacturing Ltd.

SUNTECCNC’s 4-axis wood router transformed our production. We increased output by 65% while reducing waste by 30%. The technical support team resolved our initial setup questions within hours. Excellent investment for our factory.

Precision Metal Works Inc.

The fiber laser cutter exceeded expectations. Clean cuts, minimal heat distortion, and incredible speed. Our lead times dropped from 2 weeks to 3 days. Customer satisfaction improved significantly. Best equipment purchase we’ve made.

Advanced Components Corp.

Complex aerospace parts that previously required multiple setups now complete in single operations. The machine’s precision and reliability are outstanding. ROI achieved in 8 months through reduced labor and improved quality.