Don't worry, contact your boss immediately

In the vibrant landscape of contemporary manufacturing and fabrication, precision, efficiency, and flexibility reign supreme. The advent and development of Computer Numerical Control (CNC) innovation have revolutionized just how sectors approach material handling. A common CNC router offers significant automation and precision. Nonetheless, many specific applications require capacities beyond off-the-shelf solutions. This is where the custom CNC router emerges as an important tool. A custom-made CNC router is not simply an equipment; it represents a bespoke engineering option, diligently developed and built to deal with distinct functional requirements, material obstacles, and production scales. This post delves into the details of custom CNC routing, discovering its interpretation, the engaging factors for its adoption, the substantial personalization possibilities, its diverse applications, and critical considerations for purchase.

To completely value the “custom-made” aspect, we must initially understand the fundamental innovation.

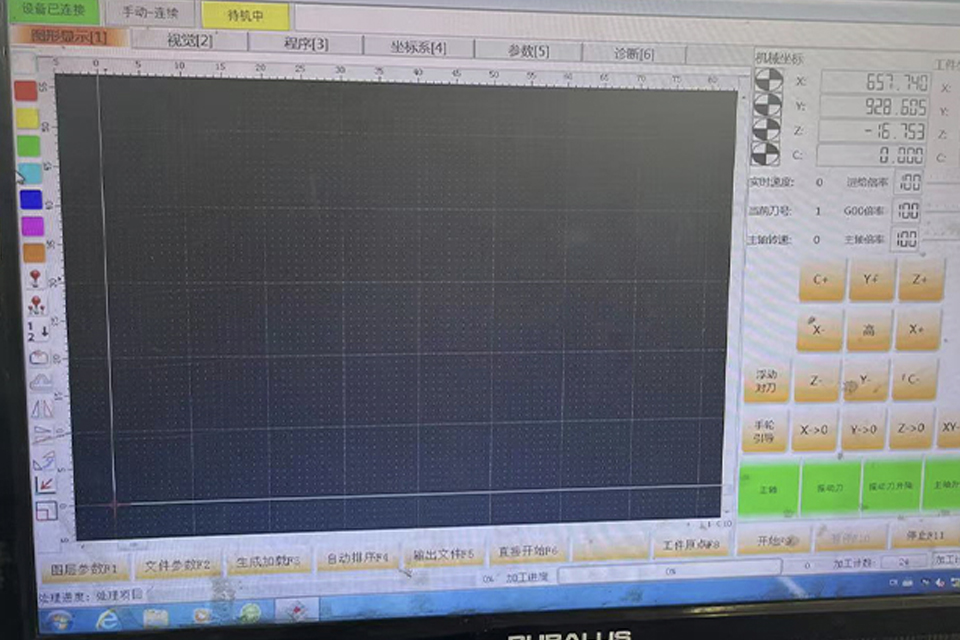

A CNC router is a computerized cutting equipment that uses computer control to relocate a cutting tool (typically a spindle with a router little bit) along multiple axes (X, Y, and Z, and in some cases additional rotational A and B or C axes). Operators create or import designs making use of CAD (Computer-Aided Design) software program. They after that utilize web cam (Computer-Aided Production) software application to translate these layouts right into G-code, a machine-readable language. The CNC controller analyzes this G-code, routing the motors to move the spindle exactly, sculpting, reducing, or engraving the work surface. This modern technology enables complicated forms and repeatable precision far going beyond manual abilities.

A custom CNC router goes beyond the limitations of standard, mass-produced equipments. Makers style and build these devices to fulfill a client’s details, commonly niche, needs. This tailored technique implies the device’s size, setup, power, tooling, and even software application interface can be changed or developed from square one. If a project requires an abnormally huge job envelope, specialized product handling, or unique reducing procedures, custom-made CNC directing offers the solution. This makes sure the equipment integrates perfectly into a specific manufacturing workflow, optimizing its energy and return on investment.

The decision to buy a personalized CNC router originates from certain functional needs that basic devices can not appropriately fulfill. Businesses that opt for personalized CNC routing frequently look for a competitive edge through enhanced processes.

Lots of projects entail products or end products that are either remarkably huge or abnormally small. Standard CNC router workbeds could not suit big sheets of plywood, large acrylic panels, or lengthy metal extrusions. On the other hand, detailed miniature job may demand a smaller, extremely stiff device for boosted accuracy. A custom CNC router allows for the specification of a specific job envelope (the physical restrictions of X, Y, and Z traveling), ensuring the equipment completely fits the range of the desired procedures. This stays clear of the inadequacy of using an equipment also huge or the unfeasibility of using one as well tiny.

Specific sectors or one-of-a-kind production processes have distinct requirements. As an example, machining unpleasant composites like carbon fiber demands specialized dust extraction and hard maker components. Handling really thick products might require extended Z-axis travel and a gantry with better clearance. Applications involving 3D sculpting on round objects necessitate rotating axes. Custom-made CNC routing enables the combination of these specialized features straight right into the equipment’s design, making it purpose-built for the job.

Different products behave in a different way under machining. Softwoods, hardwoods, plastics, foams, non-ferrous steels, and compounds each need specific pin rates, feed rates, and cutting device geometries. A custom CNC router can be furnished with a pin enhanced for the main materials it will process– be it a high-torque spindle for steels or a high-speed pin for wood and plastics. Coolant or misting systems, important for some materials like light weight aluminum, can also be integrated.

While made for certain demands, a personalized CNC router can paradoxically use enhanced adaptability. By preparing for a range of prospective tasks during the design phase, features like multiple pin heads, quick-change tooling systems, or exchangeable bed arrangements can be integrated. This permits a single personalized machine to carry out a bigger array of procedures or adapt to progressing production requires more effectively than a common machine developed for a narrower application spectrum.

Makers can enhance custom-made devices for particular, recurring jobs. This optimization frequently brings about significantly quicker cycle times. Functions like automated material loading/unloading, integrated vacuum systems tailored to component dimensions, or software program regimens for certain operations can dramatically decrease manual treatment and arrangement time. In addition, the precision of a custom CNC router, fine-tuned for certain materials and tasks, decreases mistakes and product waste, contributing to an extra affordable and lasting operation.

The term “custom-made” incorporates a huge selection of potential alterations and function enhancements. A customer works together carefully with the custom-made CNC router supplier to specify these components.

The most basic personalization entails the physical dimension of the maker. This includes the X-axis (typically size), Y-axis (width), and Z-axis (height/depth) travel. Modifications can vary from portable desktop computer designs for detailed work to huge gantry routers extending many meters for large fabrication, like boat hull molds or building elements. Beyond the common 3 axes, 4th-axis rotating accessories (for round machining) and complete 5-axis capacities (for complicated 3D contouring) represent significant locations of customized CNC routing layout.

The pin is the heart of the CNC router. Personalization choices consist of:

For applications calling for multiple different cutting devices for a solitary job (e.g., drilling, roughing, ending up, inscribing), an ATC is crucial for efficiency.

Safely holding the work surface is extremely important for accurate machining. Customized CNC routing solutions succeed right here:.

The CNC controller and its accompanying software are the minds of the procedure.

For high-volume manufacturing, incorporating product handling can be a crucial modification:.

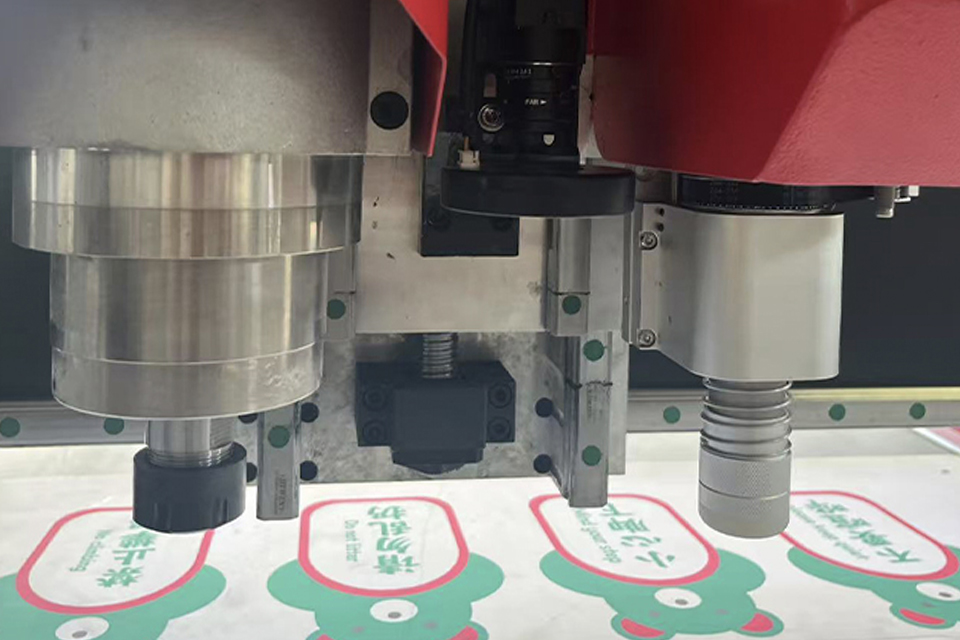

Past basic spindles, a custom CNC router can accommodate specialized reducing heads. Accumulated tools, as an example, enable tilted drilling, sawing, or routing without requiring a complete 5-axis maker. Oscillating tangential knife cutters are made use of for foam, rubber, and corrugated products.

The journey to acquiring a custom CNC router is a collaborative one. It typically involves a number of vital phases, guaranteeing the last equipment perfectly aligns with the client’s vision and functional needs.

This phase is crucial. The customer describes their present processes, challenges, preferred end results, materials to be processed, production volume, and budget restraints. The personalized CNC router maker listens, asks probing questions, and starts to conceive potential remedies. This includes a deep study the specifics of the application– what requires to be reduced, exactly how exactly, how swiftly, and in what environment.

Based on the needs evaluation, the manufacturer develops preliminary style concepts. This includes proposing device dimensions, spindle kinds, axis arrangements, control systems, and any type of specialized functions. Detailed specs are created, typically involving 3D designs and simulations to help the client picture the proposed custom CNC transmitting solution. Iterative discussions refine these requirements till both parties agree on the last style. This phase ensures all requirements are recorded before manufacturing commences.

To additionally clarify the benefits of a tailored solution, a straight contrast works.

| Function | Standard CNC Router | Personalized CNC Router |

|---|---|---|

| Style Approach | Off-the-shelf, mass-produced | Bespoke, engineered to certain demands |

| Versatility | Limited to typical arrangements | High; size, power, attributes are all tailorable |

| Application Fit | General function, might need workarounds | Optimized for certain jobs and products |

| Preparation | Shorter, commonly in stock or fast develop | Longer, due to style and personalized manufacturing |

| First Expense | Usually reduced | Normally higher as a result of one-of-a-kind design |

| Versatility | Great for a series of typical jobs | Can be extremely specialized or generally functional |

| Optimization | Generic optimization | Optimized for particular production performance objectives |

| Issue Fixing | Addresses usual production requires | Resolves one-of-a-kind, intricate, or niche difficulties |

| Return on Investment | Helpful for basic usage | Potentially greater for specialized, high-volume, or high-value manufacturing due to performance gains |

| Suitable User | Enthusiasts, tiny shops, basic fab | Organizations with details, demanding, or one-of-a-kind manufacturing needs seeking peak performance for their custom-made CNC routing tasks |

The adaptability of customized CNC router modern technology makes it important throughout a wide variety of sectors.

The woodworking sector thoroughly uses customized CNC routers. They produce complex layouts for customized furnishings, facility joinery for premium kitchen cabinetry, and in-depth makings for architectural aspects like moldings, newel messages, and ornamental panels. Large-format machines handle full sheets of plywood or MDF, while multi-axis equipments develop complex bent parts.

Custom CNC directing is essential for developing dimensional indications, channel letters, logo designs, and point-of-purchase display screens. Machines are customized to handle numerous products like acrylic, PVC, light weight aluminum, wood, and high-density urethane (HDU) foam. Features like blade cutting abilities for plastic or softer products can also be incorporated.

Engineers and designers make use of personalized CNC routers to quickly create physical prototypes from varied products. This allows for quick model and testing of layouts for customer products, mechanical parts, and ergonomic models before dedicating to expensive automation tooling. The capability to machine real design plastics or steels supplies practical models.

While heavy-duty CNC milling makers control metal cutting in these markets, custom CNC routers play a crucial role in machining lighter materials. They shape patterns and molds for spreading, trim composite elements (like carbon fiber or fiberglass components), machine interior panels, and develop jigs and components for production line. Precision and dependability are paramount, typically needing innovative control systems and robust machine building and construction.

The plastics industry counts on custom CNC transmitting for reducing, cutting, and forming sheets of acrylic, polycarbonate, ABDOMINAL, and other polymers. Applications include developing equipment guards, display cases, medical gadget parts, and trimming thermoformed parts to their final dimensions with high accuracy.

Machining compounds like carbon fiber strengthened polymer (CFRP) or glass fiber reinforced polymer (GFRP) presents unique challenges as a result of their rough nature and propensity to flake. Custom-made CNC routers for composites commonly include high-speed spindles, specialized diamond-coated tooling, durable dust removal systems, and occasionally full enclosures to include unsafe dust.

Large custom CNC routers are utilized to form foam for developing mold and mildews (e.g., for concrete or composite layups), architectural models, theatrical props, and themed setting components. These devices usually have actually extended Z-axis traveling and can be geared up with lengthy cutting tools or hot wire add-ons.

In boat structure, custom-made CNC routers are used to reduce molds for hulls and decks, develop personalized cabinets and interior components, and device complex teak wood outdoor decking patterns. The ability to manage big, typically rounded, elements is a key advantage.

Buying a custom CNC router is a substantial decision that requires mindful preparation and analysis.

Prior to approaching suppliers, extensively assess your specific requirements. What products will you process? What are the regular component sizes (min/max)? What accuracy and repeatability are needed? What is your existing and predicted manufacturing volume? Exist any certain environmental constraints (room, power)? Plainly specifying these requirements is the initial step towards an effective customized CNC transmitting service.

Custom-made CNC routers usually stand for a higher upfront investment than basic devices because of the design, style, and bespoke production involved. Develop a reasonable spending plan. Crucially, execute an ROI evaluation. Take into consideration how the custom-made device will raise throughput, reduce labor costs, decrease product waste, boost part top quality, or enable new company chances. The long-lasting advantages need to justify the first expenditure.

Selecting the appropriate supplier is paramount. Seek a business with tested experience in designing and developing personalized CNC routers for applications similar to yours.

The supplier must offer comprehensive setup solutions and extensive driver training. Ensure your team understands exactly how to operate and keep the custom-made CNC router safely and efficiently. Make clear the regards to the guarantee and the availability of recurring technical assistance and maintenance services. A strong assistance structure lessens downtime and makes best use of the maker’s life expectancy.

The area of custom-made CNC directing is not fixed. It continues to develop, driven by technological improvements and the ever-increasing needs of contemporary sector.

Future custom-made CNC routers will likely feature deeper combination with Sector 4.0 principles. This consists of improved connection for remote surveillance, diagnostics, and anticipating upkeep via the Internet of Things (IoT). Equipments will certainly communicate better with various other manufacturing facility systems, enabling even more streamlined and computerized production workflows.

Expert System (AI) and Machine Learning (ML) are positioned to play a higher duty. This can materialize in self-optimizing cutting criteria based upon material comments, intelligent device wear detection, or automated G-code generation for intricate parts. This will further boost the efficiency and autonomy of customized CNC transmitting procedures.

There will be a raising concentrate on designing customized CNC routers that sustain sustainable manufacturing practices. This includes optimizing for power performance, reducing waste via smarter toolpaths, and adjusting to process brand-new, environment-friendly products as they become available.

A custom-made CNC router stands for a tactical financial investment for organizations intending to attain exceptional accuracy, performance, and versatility in their product processing procedures. Moving past the one-size-fits-all method of conventional machinery, custom-made CNC transmitting remedies are thoroughly crafted to meet details application demands, product qualities, and manufacturing scales. From the first examination and design phase with to production, setup, and recurring assistance, the advancement of a custom CNC router is a collective venture that empowers organizations to overcome one-of-a-kind manufacturing challenges, unlock new capacities, and obtain a considerable competitive advantage in their corresponding industries. By carefully considering their demands and partnering with experienced manufacturers, companies can leverage the power of personalized CNC directing to transform their manufacturing procedures and attain new heights of operational quality.